Linen Ordering Patterns: Why Consistency Matters

Just like your patient census fluctuates, your linen orders should, too. Orders that increase or decrease by a similar percentage to your patient load help both your facility and our processing plants stay efficient and well-prepared.

It’s not unusual for orders to be close in size from one delivery to the next. In fact, consistent ordering is a sign of good par management. It allows Crown’s teams to anticipate what’s coming back as soiled linen, plan staffing more accurately, and ensure we have the right amount of inventory available to meet every customer’s needs.

The Ripple Effect of Over-Ordering

Ordering more linen than your facility needs might seem harmless, but it can create challenges for both your team and ours:

- Storage limitations: Over-ordering fills up valuable storage areas and often leads to linen being stored in hallways, patient rooms, or other non-designated spaces. These practices compromise infection prevention and make the environment appear cluttered and unorganized. A cluttered environment can negatively affect patient perceptions of cleanliness, which directly impacts HCAHPS survey scores on how clean the room was kept.

- Cycle of hoarding: When linen is abundant once or twice a week but scarce the rest of the time, staff begin to “stockpile” early. This creates an uneven flow of linen, artificial shortages, and added stress for both floor staff and Crown delivery teams.

- Artificial loss numbers: Inconsistent ordering can distort usage data, leading to linen losses appearing higher than they actually are. This complicates reporting, distorts benchmarking, and leads to unnecessary linen replacement costs.

- Operational inefficiency: Uneven ordering affects delivery planning, plant production scheduling, and space utilization at both the healthcare facility and processing plant, resulting in extra handling, misplaced inventory, and wasted effort on both sides.

- Negative patient experience: When the correct size or item isn’t available, substitutions become necessary. That “average-size patient in a 5XL gown” scenario doesn’t just waste linen; it directly impacts comfort, dignity, and satisfaction.

Finding the Right Order Balance

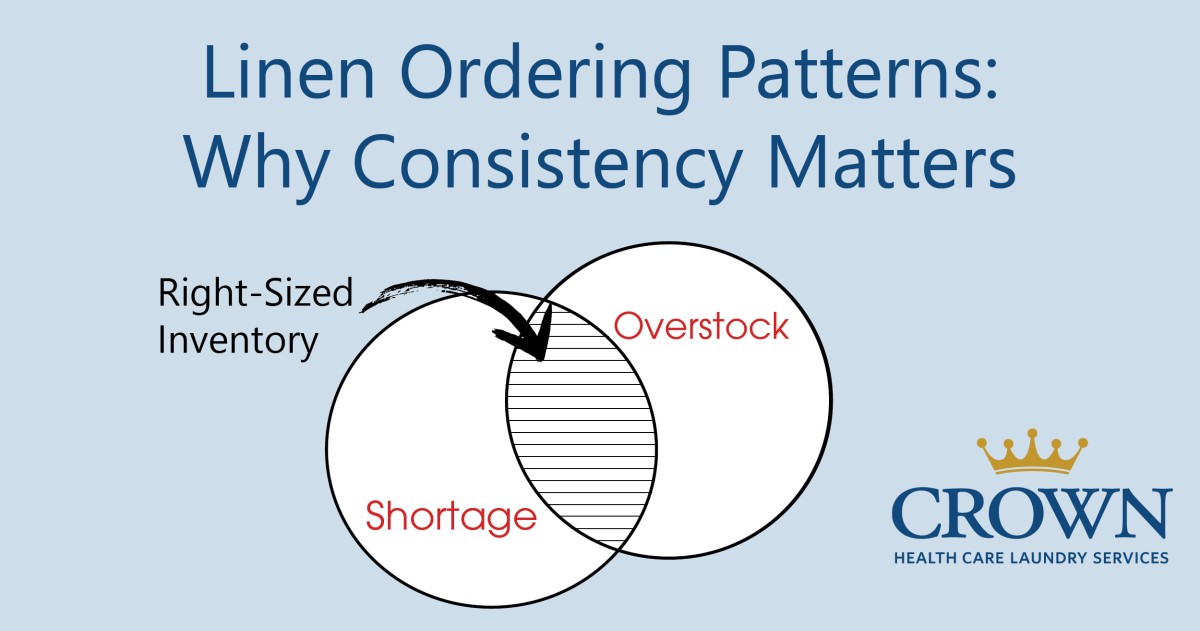

Consistency doesn’t mean every order should be identical; rather, your totals should closely align with your actual usage and delivery schedule.

For example, if your facility receives linen three times a week — Monday, Wednesday, and Friday — and averages 1,000 sheets per week, each order should be around 330 flat sheets. Ordering 650 on Monday and 200 later in the week creates inefficiencies and storage challenges unless your patient or procedure volume is significantly higher early in the week.

For a six-day delivery schedule with about 8,000 washcloths per week, daily orders should range from 1,300 to 1,500, depending on your average census. These small adjustments help ensure the right amount of linen is available when it’s needed most, without creating waste or storage challenges.

No matter how often your facility receives linen, clearly posted par levels in the linen room are one of the simplest and most effective tools for monitoring usage. A quick glance can reveal over- or under-ordering patterns. For example, if the posted sign says “1,000 washcloths on the shelf,” but the shelf is empty or linen has migrated into another area, that’s a clear indicator of fluctuating habits. Par level postings are among the first things we look for when a facility reports shortages or overstock, and among the first recommendations we make to improve utilization.

If your team prefers not to place multiple orders each week, your Crown service representative can help evaluate your par levels or establish a default order reviewed monthly or quarterly. (Please note: maintaining higher par levels to support a default order may result in higher costs due to additional inventory in circulation.) For facilities that receive deliveries multiple times each week, it’s still recommended to place at least one manual order in addition to the default. This small step allows quick adjustments when census changes unexpectedly and helps prevent shortages or excess inventory.

Think of linen ordering like grocery shopping: would you buy all your groceries on Sunday, eat them by Tuesday, and go without until Friday? Probably not. Steady, right-sized ordering keeps your operations balanced, your space organized, and your patients satisfied.

Reducing Linen Loss in Acute Care

For facilities looking to reduce or prevent linen loss charges, maintaining balanced orders and pulling soiled linen in a timely manner becomes even more important. Inconsistent ordering and delayed soiled linen returns can make linen usage appear higher than it truly is.

Many employees who place linen orders focus on ensuring patient care needs are met and may not realize that par levels, soil returns, and order timing all connect to accurate loss tracking. Taking a few minutes to review these processes as a team can go a long way toward reducing costs and strengthening linen management overall.

The most efficient way for hospitals to manage par levels and order exactly what they need is by using LinenHelper, a free, cloud-based software offered to Crown’s hospital customers. It tracks usage, identifies trends, and helps acute care facilities stay consistent without overstocking.

Best Practices for Clinics and Outpatient Centers

For smaller facilities, storage space and staff time are often limited, making smart ordering even more impactful. The key is to keep orders consistent, right-sized, and tied to your actual appointment volume.

- Match orders to your schedule. Adjust linen quantities based on upcoming volume changes, such as before holidays, seasonal slowdowns, or provider vacations. This helps prevent buildup during slower weeks and shortages during busier ones.

- Split orders evenly. If your clinic receives two deliveries per week and averages 300 towels, ordering about 150 per delivery keeps inventory balanced and prevents the “mountain on Monday, shortage on Thursday” problem.

- Skip the “just-in-case” extras. Those extra packs often become long-term overstock, take up valuable space, and may even lead to misplaced or discarded linen. Overstock at one location also ties up inventory needed elsewhere, forcing plants to purchase additional stock to fill the gaps, which ultimately increases costs across the system.

- Keep linen in designated clean storage. Avoid storing linen in patient care or mixed-use areas, which can compromise infection prevention standards. Clean, organized storage protects the product and reinforces compliance.

- Partner with your route driver. Drivers often notice usage trends first-hand — overstock, missing items, or unusual return patterns. A quick conversation during delivery can help fine-tune your orders before small inefficiencies become larger losses.

Right-sized, consistent ordering keeps linen fresher, reduces rental costs, prevents clutter, and allows your team to focus on what matters most: patient care.

We’re Here to Help

Crown’s goal is to help every customer manage linen efficiently, economically, and safely. Whether your facility serves hundreds of patients a day or just a few dozen a week, we can partner with you to review ordering patterns, assess par levels, and provide the tools that make linen management easier.

Smart ordering means smoother operations, less waste, and better patient experiences. Have questions or need assistance? Click here.